209XR is a wonder material and priced accordingly. The outgas is horrific but it will set up under water in cold conditions. The setup has 2 stages

- Initial adheasion

- Outgas curing

The 208R will not work as well in cold. It is too stiff and requires WAY too much force to apply (get your initial adhesion). It then does not have sufficient “properties” (elastomer or polymer) to sufficiently cure as the solvents evaporate

- 208R in the Hot Wet

- 209XR in the Cold Wet

If you want to get into regular old 208… that testing is not of interest to me.

….

Next Up?

Preemptive Dry Applications which are not (felt + grip tape), are low cost, can cross-pollinate to mobile and non-wood applications.

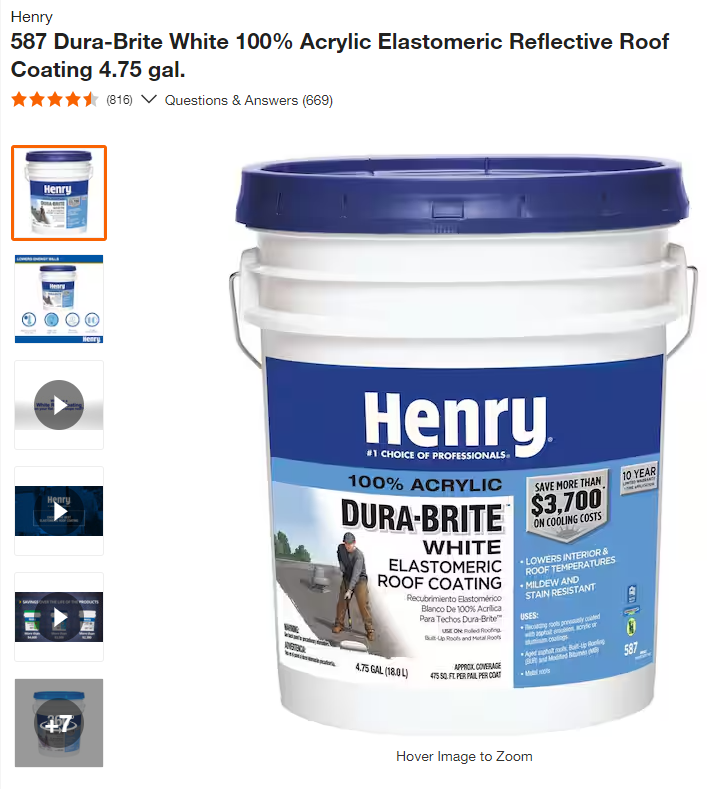

Roof Coatings!

….

Then after that

- Actual Roofs

- Applied to Specification

But … by Schindlers Method… we master an activity by first learning the W H Y of proper methods and ways by S U F F E R I N G the consequences of alternate methods and ways. Folks who live in an RV will understand.

- You cant use “Roofing Technology” to fix your RV ( LOL)

- Just picture someone rolling on grip tape (aggregate) with felt (LOL)

- They are F A R more likely to converge on a Silicone or Acrylic roll-on

And… that is what we are actually after here. What materials from the “Roofing Community” can we harness in the building of Solar Outhouses.

Assume-not… that a solar outhouse will be made of wood and stationary! It is far more likely to be built of salvaged materials and mobile. That being the case, my studies into “Patch Materials” (specifically WET patch) are paying out dividents.

SURE

Anybody can wait until the hottest summer day to perfectly apply a bead of clear silicone. That aint the day that you will discover roof leaks on your 42KWH battery.

You are welcome

-Schindler