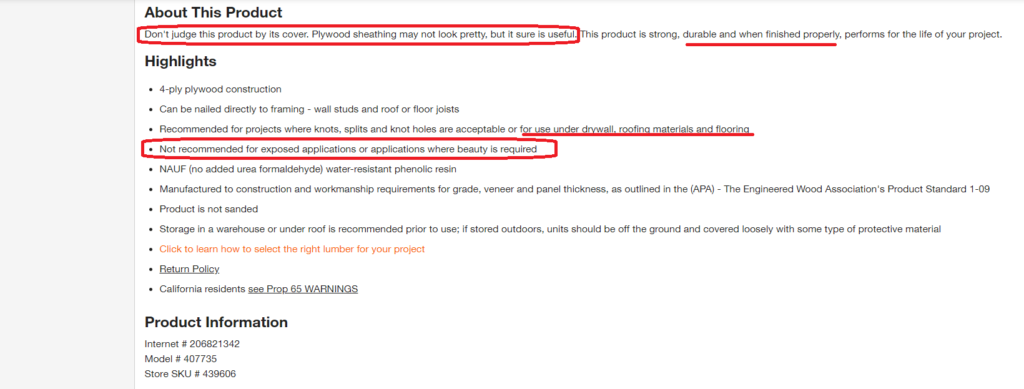

Home Depot 19/32 (~5/8″) Plywood

Read the description for a good laugh.

They ARE quite honest and I am clearly using the material outside of specification. Too bad I did not read that description before picking up a load of them! Obviously they can not perform 100% inspection. As they average out over 100,000’s… they are a good value

BUT

What happens in practice is that every asshole in town “sorts the stack” taking the select materials from the pallet, leaving behind a concentration of fucker’ed wood. That is to be expected* …

WHERE THE TROUBLE LIES

Is that Home Depot does not have a clear enough policy by which to dispatch with “the bottoms” of what is left after the fearless men and woman perform the first distillation. It turns out they (Home Depot) DO have a policy, but you have to know about it. Basically, if you are willing to take the fuckered wood, they will give you a discount. Anywhere from 20% to 70%, depending on fuckered-ness

AT TIME OF PURCHASE, I WAS NOT HIP – DOH

So… Schindler over here is now “testing” (aka stuck with) some of the absolute worst plywood available in a grossly exposed condition.

Many of these clearly do not hit the advertised specification. The knot holes are fine, but you cant have too many of them grouped together on different laminations.

Anyhow, that is not what this story is about. The prices of wood went INSANE during COVID and I was happy to be able to get any wood at all! I will admit that I was caught off guard when this plywood did not perform like plywood’s of the past…

BUT

They clearly state in the description that the wood is garbage. And… the wood presents as garbage. So… sigh… Schindler has to own this folly.

O N W A R D

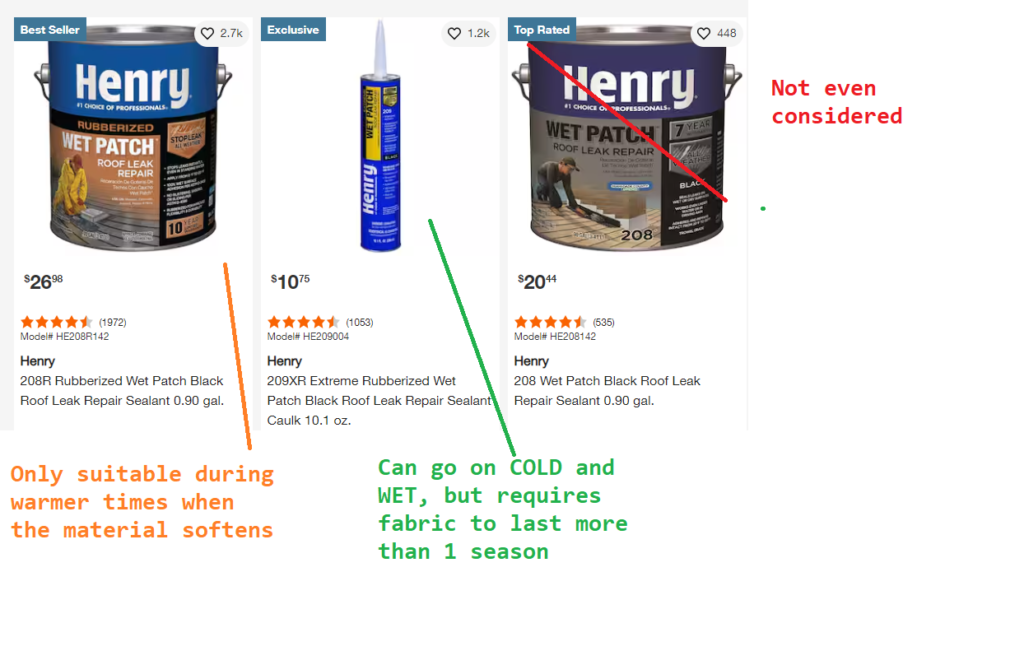

To how to make due with what is available. Elasticized Roofing Tars that are Wet Application Rated.

FINDINGS

- 209XR is the real deal but expensive

- 208R is too stiff in the cold

- 208 is not in the running

In every case I applied under harsh conditions. Often cold but always wet. I found the following in my experiment

- 209XR without fabric will last up to a season but will fail on you. This is where you just gum the seams with an overcoat

- 208R with fabric applied in the cold can result in mass delamination’s, EVEN IF… you felt like you had sufficient bond at time of application. There is the initial bond then the bond that occurs as the volatile solvents evaporate. In the cold/wet the 208R simply does not perform as well as the 209XR. It is S T I F F… and it does not set up as reliably. I would use the 208R in the Summer

At this point I dont know how many seasons I am in to my testing. At least 2, maybe 3. I have all my seams patched and now I am on to what Engineers call “Latent Failure”. These are 2nd order and 3rd order failure modes which do not appear for many months or years.

OBVIOUSLY

If you practice proper roofing you never experience any of this. That is a different exercise. What we are doing here is “Shed Technology”. How do you use nothing but plywood and some goop to make a low slope flat roof that holds up

TL;DR

- You will develop leaks

- You will then have to patch those with cloth

- The cloth will then create high spots

- High spots create puddles

- Puddles exasperate low quality plywood

- Blah blah blah

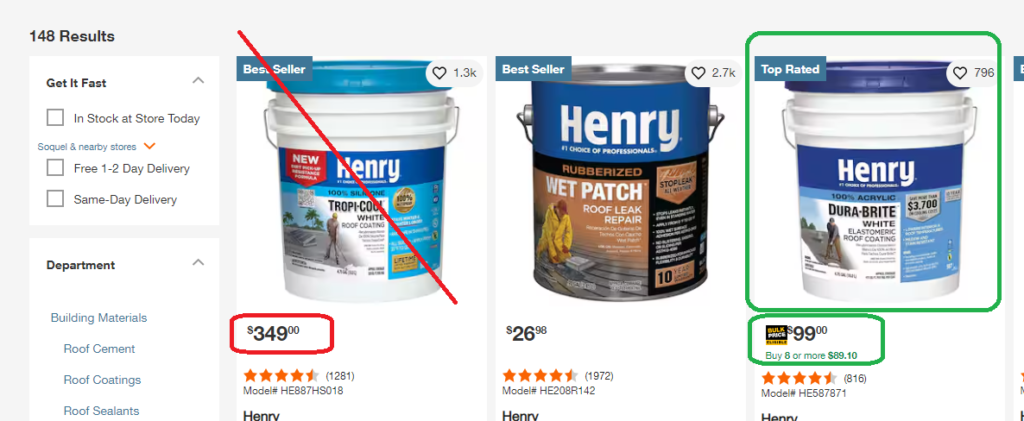

So… The next thing we are going to evaluate is the Roll-On cheap sealant. NOT the silicone! The Acrylic.

That will upgrade the underperforming plywood to a standard that MIGHT actually pass the 5 year test.

So if I had it to do over….

And assuming we do not use “standard” roofing practices…. (which OBVIOUSLY work)

I would go about it like this

- Double rafters around any joints to allow for secure attachment

- Stagger placement to avoid continuous seams

- SPACE the plywood with at least a 1/8″ gap, maybe 1/4″ or more

- Fill the gaps with Silicone in the summer or 209XR in the rain

- After everything cures, roll $99 of Acrylic over it (can be re-applied)

That should result in a ” low slope shed roof” that has the following properties

- Does not buckel

- Does not buckel

- Does not buckel

- Does not leak

- Appears Uniform (white)

- Not too slippery (silicone has a lot of issues…)

- Not involving felt, tarpaper, roll-on roof

At the end of that fight… you will come to an even better conclusion

- Stagger your plywood, dont bother doubling rafters

- Gap your plywood to avoid buckling, or KEEP IT DRY

- Felt the entire surface, think of felt as tar paper or a vapor barrier

- Roll on the grip tape and seal the seams

- Dont trap any water, let it escape on the down hill side

We will eventually work toward that, but not until I extract the MAXIMUM LEARNINGS from my Roofing Adventure.

At present

- Two leaks

I just patched those with 209XR, under water, on a cold morning, using roofing toilet paper. We will see how it holds up. Those fucking knot holes are what got me! I painted all my plywood with a primer sufficient to fend off SOME water… but… not enough. Any pooling water what so ever will find one of those knots… and

- 5 plys

- Knot at the top

- Connects to middle channels and knots

- Ends at a knot inside that drips on my head and batteries

Sigh

Quite the adventure this has been. It will probably end with me tearing up the temporary work and finishing with something that actually works. In the mean time… I have enjoyed >90% dry work area for my fumblings.

-Schidler