This adventure has been all about BOATING!

Since we moved closer to the sea (we are a block from the harbor small-craft launch now…) interests have shifted to powered water craft. Where we are ultimately headed is a Zero Motorcycles 75-7 driven by a Sevcon Gen 4 in size 6… but before we jump into that we had to freshen up on some basics.

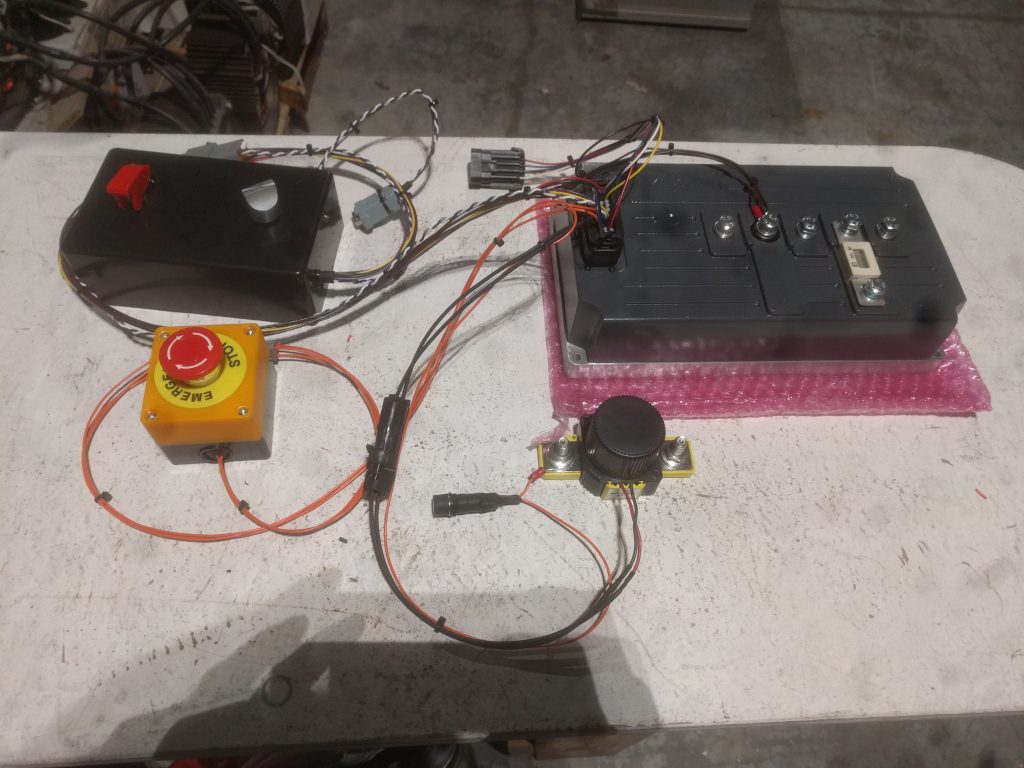

Here is a pic of the Size 6 Sevcon with a custom harness that we spec’ed and built from scratch over at Calfee Design

Of course that all gets split-sleeve for abrasion and overall aesthetic but you get the idea.

The motor will look a little something like this:

That is an up-cycled Zero motor that has been carbon wrapped on a lathe and drilled for ventilation. That particular motor has an interesting future … ours will be a bit different.

Transoms:

The Transom is the mounting point on your boat for the motor. In this case… a small electric outboard you will recognize as a “Trolling Motor”. These motors can be quite over-volt friendly…

You will notice that is a REALLY ROUGHED OUT example. We built this from no plans in 45 minutes using nothing but some cabinet wood we found in the garage, an angle grinder (no saw!), and a drill.

The assembly mates to the plastic Kayak via blind rubber nuts… you basically over drill, insert, and expand. They work quite well and do not damage the kayak in the process.

In the spirit of ROUGHING OUT A PROOF OF CONCEPT we picked that Trolling motor up for free in Laselva, nabbed the battery out of my car, and headed for the harbor for a test run.

Testing, testing, testing… I cant say it enough!

At Schindler Engineering – before we dive head first into an expensive venture we spend AT LEAST 20% or 30% of our time bounding the problem. We start simple and cheap… with a test that will help us understand what sort of hurtles we will see as we start to scale.

If the 2 person Kayak is hard to handle on 30lbs of thrust… it will be unmanageable with 300lbs. 🙂 Seems obvious, but you would be surprised at how often we have seen a system getting finishing touches that fundamentally just will not function well.

So with the boat in the water and a better understanding of how it will load down under the weight, how the steering will feel, whether it will need stabilization… we decided further testing was in order.

Off to Washington… our official test site for all things ridiculous.

Here is a shot of our test fleet:

The Trusty Aluminum cruiser, the not so trusty foam floater, and the ultralight inflatable.

For the record… the foam bit of business up there was built by Mathew R. back around 2013. We were on holiday and I challenged him to make a seaworthy vessel in less than 15 minutes. That’s what he came up with… quite clever… and so as soon as he announced completion I tied a rope to it, asked him to board, and took off across the canal! Lol… We motored until the battery died and then I rowed him back in. Confirmed… his vessel was indeed seaworthy.

Mk2

Weight and draft is everything… followed closely by steering and the ability to stay afloat. This fine vehicle can be hand carried with ease but is hell to steer. Right off it is clear that we will need a boat which is not flat bottom if we are going to harness the Zero Power Train…

It needs to be light… it needs to hydroplane to some degree… it needs to turn on a dime WITHOUT FLIPPING. (Reference future photo which is not yet taken of the 5 gallon jugs on a boom we will soon add to the test Kayak)

So… all of these rigs have been slow so far

(Unlike this snail we found at low tide which when fully extended was the size of a cantelope)

But…. just like a goat in a diaper with a cast on its leg at a laundromat…

Good things start small, Fast things start slow, and boats with enough power never sink!

Until next time… on Adventure

-Patrick